Metal 3D printing is the solution to optimised cost, weight and performance aerodynamics

3D printed metal parts of bridges, crowns and abutments in titanium are the preferred choice in implants

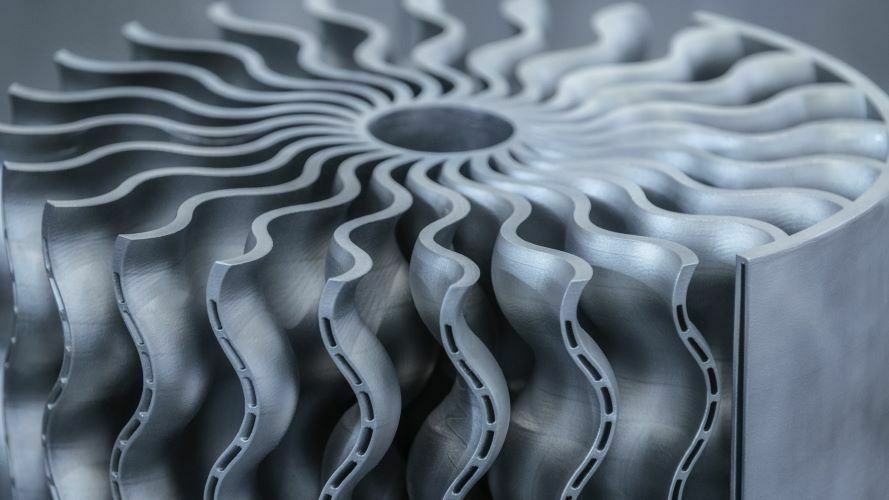

Complex lattice stuctures to maximise surface area and minimise weight for efficient thermal energy transfer

Additive Engineering is an ISO9001:2015 certified advanced manufacturing facility.

Each member of the Additive Engineering team has been delivering customised 3D printed products and repeatable metal 3D printing / additive manufacturing parts to industry for 10 to15 years.

Metal AM is not all we do. Additive Engineering 3D prints in plastics too, have extensive experience in CNC machining and injection moulding, we dedicate our passion in metal 3d printing technology to understanding material mechanical properties. We live and breathe metal 3D printers and 3D metal printing (with safety masks on) so you can be assured our recommended material and manufacturing process is best for your part.

With metal 3D printer experience ranging from Concept Laser, 3D Systems, Desktop metal printers, HP metal jet and Markforged metal X, technologies (laser metal deposition, direct metal laser sintering, electron beam melting) and powder materials including precious metals, titanium and stainless steel, the team has an in depth knowledge of metal additive manufacturing, metal powder handling and how to best manufacture complex metal parts. We can explain why parts made with metal filament technologies are not comparable in mechanical properties to the process of laser completely melting powdered metal. To learn more about 3D printing materials or help with mishaps, call us.